About Us

Incepted in the year 1995, we "Brissun Technologies Pvt. Ltd.," are engaged in manufacturing and exporting optimum quality processing plants and equipment for meeting the processing needs of edible oil, alcohol and bio-fuel. The offered equipment are widely recognized for offering robust construction, high performance and durability standards. Led under the able leadership of our mentor, Mr. Vivek Bansal, who has with him extensive industry experience, we are successfully meeting the specific process equipment demands at client's end. His understanding of industry dynamics has also helped us to provide customers complete satisfaction in terms of the overall functionality of the equipment delivered/installed. Our state-of-the-art manufacturing unit has also been one of the major contributing factors in our success. Owing to our well established and maintained resources, we have also been able to export our equipment range to various countries all across the globe. Furthermore, we also undertake effective along with meeting the demands of spares and after sales services for all types of projects & machinery.

DESIGN & ENGINEERING

Design and engineering is done with the help of CAD / CAM, computer aided software and professional engineers with 25 plus years of experience in the field. Our draftsmen are experienced and are proficient in handling P & ID, Structural Layouts and all the detailed piping layouts as per site requirements.

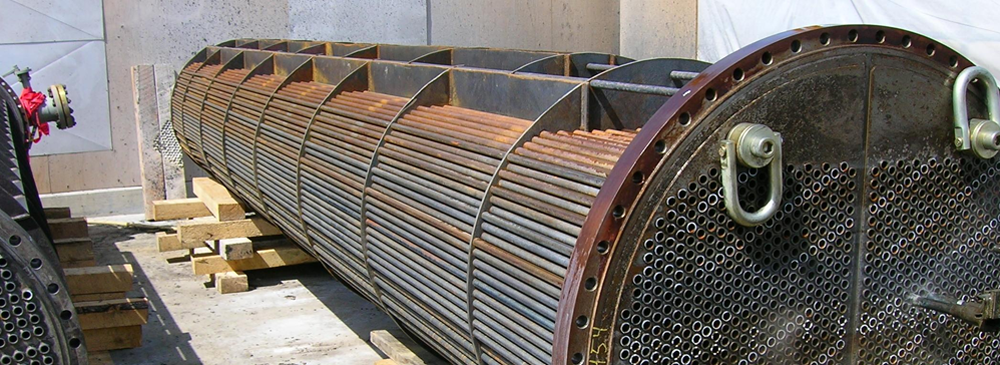

MANUFACTURING FACLITY

The company has a state of the art manufacturing setup consisting of a covered shed of 15000 sq. ft. and open area of about 35000 sq. ft. near General Motors at MIDC Talegaon, India. The fabrication shed consists of modern welding machines, overhead crane for material handling and skilled manpower with over 15 years experience n manufacturing of process equipments as per ASME code, Section VIII, Division I. Address Gat No: 119, Vill: Amble, Tal: Maval, MIDC Talegaon, Pune – 410607.

TESTING FACILITY

Every piece of equipment fabricated undergoes hydraulic pressure testing as per design specifications. Radiography of weld joints is done as per ASME specifications. Welders are qualified by third party inspection agencies and inspection is also done for every piece of equipment by a third party inspection agency appointed by us to make sure that our customers get the best in terms of quality.

ERECTION & COMMISIONING

We have a team of trained site engineers to take care of the erection and commissioning of the project. They are experts in their field and have the ability to execute the work effectively and efficiently so as to deliver the project on time.